Painting time for N14YT

May 2016This write-up will be updated as the process changes. Usually I prefer to complete a task fully before writing, but at this point in the build, I'm not wasting much time when I'm not working on the plane, so I will write as I have time, and just update it as I go.

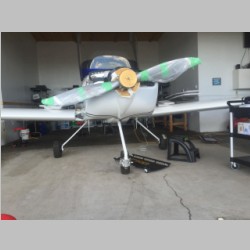

Having completed most everything I can get done before moving to the airport, and reaching our warmer months, it is now time to get this thing painted and out of our garage. It's quite a process, to paint an airplane. There is a lot of preparation that goes into the parts, and until you have them primed you never really know if your sanding job was smooth enough, or if you got out all of the pinholes in the fiberglass. So you spend hour after hour, sanding, fairing things in, spraying on a guide coat to inspect your surface, and sanding again. Eventually you come to a stage where you must move on and actually throw down some paint. I would like to say that I corrected every ding, and will have the perfect airplane and paint when all is said and done, but alas, if you want your airplane to fly, you have to get past that anal stage and understand that there will be imperfections. It's a D-I-Y airplane, by definition, built by an amateur. So as I completed some of these parts in preparation for paint, I pictured my currently flying RV-10 and all of it's imperfections, and realized that there were diminishing returns on the investment towards perfection...and it was finally time to call it good enough. Time to throw on the paint and start to use this beast!

For me, part of the pride in building this airplane is being able to say "I did this." From this Man's perspective, I can say it's most comparable to having a baby...in some ways more than you'd first think. When it's first born, it's going to be ugly. Yes, babys are wrinkly, squished up blobs of human with more fat rolls than...well, people from my region in the cheese state. The airplane is an ugly mess of ding'd up metal, pinholed fiberglass fairings, rough body filler, and other war wounds from it's birthing process. But, just as with the baby, you created it. Both the airplane and the baby will become even more beautiful as they are completed. Both of them will give you years of enjoyment, and both of them will end up costing you gobs and gobs of money as they live on. And inevitbly, when you finally have to turn them over to someone else, you'll have to deal with the pain, I suppose. I wasn't willing to hand off the paint to someone else, because it is something that I feel I can accomplish. Building an airplane requires you learn many new skills. We build for "recreation and education" in the amatuer built community...that's the philosophy. Painting is just another skill that needs to be learned, and by learning it, you are adding to your personal capabilities. Not just to maintain and repair your own airplane, but you can use these skills for other repairs on vehicles as well. So with that in mind, I would at least want to be tightly involved in every process of building my airplane.

One other determining aspect of aircraft painting, is the high cost. These days, even a quart of paint is fairly expensive, but when you try to buy that paint applied to a vehicle, the costs go up astronomically. Back in 2006, when I finished my RV-10, the average paint job cost probably $10,000-12,000. I was able to finish mine for somewhere in the neighborhood of $2000-2500. These days I'm hearing that the average paint job cost is more in the $12,000-15,000 range. I was able to purchase all of the paint and other supplies for this paint job for just over $3000, and that was going with fairly expensive paint. That's 4x-5x the price for the labor to put it on the airplane, which just wasn't justifiable for me. I know I can paint something that will look reasonably good, so why hand over a few months of pay for something I can do myself?

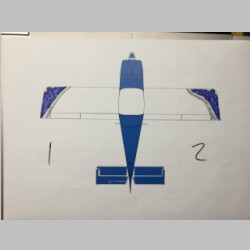

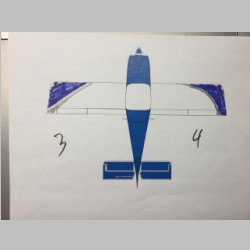

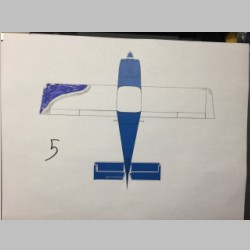

The first task in painting is determining the paint scheme. I'm not much of a fan of 2-color paint jobs, so I automatically went for 3 colors. And in this case, I wanted to have the exact same 3 colors as my RV-10 paint job, because I liked that choice so much. But, I wanted a slightly different scheme. I didn't want to copy anyone else's paint scheme, but as it turned out, Van's factory demonstrators were very good looking and were right along the lines of what I was hoping for. I'm not the biggest fan of their blue and black choice, but I think the silver looks great.

I also wanted to keep a fairly simple scheme, because A) Simple is appealing to me, B) Simple is easier to paint, and C) You'd be surprised how many people I've met who prefer simple schemes...I think resale will be easier if you keep things to standard colors and patterns.

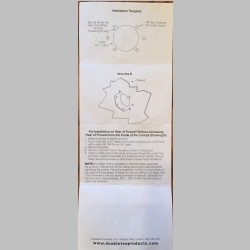

I drew up the below schemes using a paint program. I really was hoping to make it even easier by putting the N-Number in the blue as in the 3rd shot, but I believe I underestimated the letter size when picking the font, and if I sprayed it that wy it would be partly on the curved upper part of the empennage. So most likely when all is said and done, I'll be taping off and painting what's in image number 1. The details will be more apparent once it's time to tape it all up onto the actual fuselage.

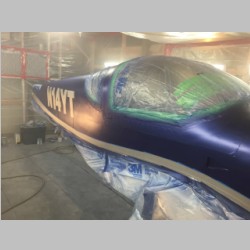

For the N-Numbers I really wanted to go with an outline font. It's harder to paint and get right, but looks awesome when done. Also, it's my opinion that the only way to go is 12" n-numbers. You built this plane...you picked the number. Be proud of it and display it for all to see. Not only that, if you plan to travel outside the US borders, you're going to need 12" letters anytime you go, so best to just paint them that way.

My numbers were created by using a vinyl stencil created by a sign shop. It makes the numbering really easy.

|

|

|

If you've read previous entries in my build log, you've seen that these are my RV-10 paint colors I've used, and that I had intended to use PPG Delfleet paint. That didn't end up being the case, now that I've actually purchased the paint. I did end up going with exactly the same paint as I did for the RV-10. It's held up pretty well, and I was familiar with the application process. But the real kicker was the availability. Doing a paint job on an aluminum airplane with fiberglass parts requires a variety of different paint and primer compositions. Fiberglass parts get primed with an expoxy primer, then overcoated with a high-build sandable primer to fill and smooth any spots. The aluminum gets a chrome etching primer, that chemically etches into and grabs on to the aluminum. (although some say you can also use the epoxy primer) Then both of those sections get covered with a sealing compound to seal them up and prevent bleed through into the paint layer. For the white paint, I'm using single stage again, for ease of application and potential repair. For the blue and silver I decided, against my own previous comments, to go with a base/clear combination. This was mainly driven by the fact that I was doing it myself. It's harder to get the metallics in paint to look smooth, with single stage paint. And me being an amateur, I figured I'd stick with the very simple application of the base coat with metallic. The clear is also very simple, and it looks great when done. So there are a variety of products you get, and in the Delfleet line, things like the etching primer weren't a stocked item. Had I been able to get everything, I may have gone that route, as the paint price is approx. $400/gal for the PPG concept I'm using, vs $250/gal for the Delfleet. But when you need more paint, you don't want to wait for it to be ordered.

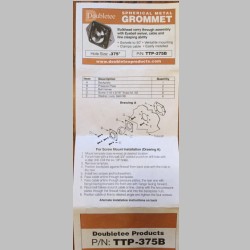

For more on the specific paint, here is a listing along with data sheets, of the items I used:

- PPG ShopLine JX101 Wax and Grease Remover

- DX1791 / DX1792 Self Etching Wash Primer

- DP48LF Epoxy Primer / DP401LF Catalyst

- K36 Primer Surfacer / K201 Catalyst / DT870 reducer

- DAS3021 White V-SEAL Acrylic Urethane Sealer / DCX3030 Hardener / DT870 reducer

- PPG Concept DCC Acrylic Urethane Paint / DCX61 Hardner / DT870 reducer (Single Stage)

- PPG Deltron 2000 DBC Basecoat / DT870 reducer

- Deltron DCU2042 Speed Clear / DCX61 Hardner / DT870 reducer

|

Final Materials Recap

6/2016 This is a follow-up to the materials listed above, to let you know how much material I used. The price listed did climb just a little bit, due to my poor planning (from lack of experience). PPG JX101 Wax and Grease Remover: 2 Gallons worked out well for the project DX1791 / DX1792 Etching wash Primer: 1 Gallon of each was probably double what is required. After finishing the project, I think if I were doing it again, I would skip this step completely and instead buy more of the DP48LF Epoxy primer and catalyst to use as the base primer. I think the adhesion would still be great, and that may possibly prevent you from having to use the sealer, which is used to seal over the etch primer. DP48LF Epoxy Primer / DP401LF Catalyst: 1 Quart. This was used over the fiberglass parts as the first layer of primer. I don't remember needing a 2nd quart, as there really aren't that many fiberglass areas on the plane. If you use this primer for the aluminum, you will probably need 1 gallon total or maybe an additional quart or so. Note: the quantity listed is for the Primer. The DP401LF just buy the amount needed to match the number of quarts of primer. K36 Primer Surfacer / K201 Catalyst: 2 Quarts. This was also only used on the fiberglass parts. I maybe could have gotten by with only 1 quart, but with the pinhole filling I needed more. This is a thick high-build primer so it sprays out pretty fast. 2 Quarts may be a good plan. Note: the quantity listed is for the Primer. The K201 just buy the amount needed to match the number of quarts of primer. DAS3021 White V-SEAL Sealer / DCX3030 Hardener: 1 Gallon + 1 Qt. This I used on the aluminum areas of the plane, and I think you may be able to eliminate it if you used Epoxy Primer...although this stuff does flow and spray very very nicely. I bought 1 gallon of white and 1 quart of a dark charcoal. In the end, I'm guessing I have at least a quart left, so it is likely that if you use etch primer + sealer you can get by with a gallon. It only requires 1 coat to seal. I would go with the white if you do a white paint over it, or grey if not. Having a slightly contrasting color makes it easier to see where paint needs to be thicker at that stage. Note: I may be mis-remembering on the DCX3030...something tells me I needed 2 quarts, to mix 1 gallon. PPG Concept DCC Acrylic Urethane Paint: 2 Gallons. This was used for my white. 2 Gallons was about right. I think I still have enough left to do the wheel fairings. If not, I'll have to buy another quart. Deltron DBC Base Coat Paint: 3 Qts Blue + 1 Qt Silver. This is the most expensive of the chemicals you buy. The DCC white was a bit over $420/gal. The Blue was $175/Qt. Had I known I'd use 3 Qts I think it would have been cheaper to buy 1 Gallon of Blue. I wish I'd have done that. 1Qt of Silver was about right. So when you see my plane, if you intend on that much of the color, then consider a gallon...or at least price it out as multiple Qts vs 1 Gallon and see what the difference is. The blue, at $175/Qt without tax is about $700/gal. (ouch) Deltron DCU2042 Speed Clear: 1 Gallon + 1 Qts. This one hurt a bit because I over-mixed a few times, and wasted some clear. This caused me to accidentally open my separate quart. It's not super cheap stuff...but I could have done it in 1 Gallon, I think, if I'd have been careful. But make sure you have extra on hand because if you run out it's a pain. I purchased 6 total quarts worth, and returned one unused quart. DCX61 Hardener: Unknown...maybe 4-6 Qts. You will want to buy enough for all the paint you purchase. I don't remember the exact quantity you use, but I know you mix it with the DCC White, and the Clear. I'm thinking I bought 4-5 qts for the total job. I don't know if it's available in the gallon...if so it may save money that way getting 1 gallon and then additional quarts. One complication is, the cap glues itself on with this stuff, so clean the spout each time if you use a gallon or you may have a hard time getting it open later. DT870 Reducer: Unknown...maybe 8-10 qts. I'm probably over-estimating here, but it's cheaper. If you buy by the quart it's probably in the $30's per quart. By the gallon it's in the 70's. So you're absolutely better off buying in gallons. You will use at least 2 gallons, I'm sure. What happened to me in re-spraying the wings, is that I ended up needing some DT885 also, for higher temp days. So this all depends on the weather you plan to spray in. You may need DT870, and DT885, or even other. My suggestion is to plan on the WX but then buy some other that will help you if you think it may fall either above or below the temp range you expect. Like I wish I'd have bought 1 gallon of DT885 and 2 gallons of DT870. You can mix them to be in between, and if it's too hot, you can add extra DT870 to thin it rather than use DT885...so it's versatile. Just buy more than you need by a gallon or two, and consider your temperatures. One thing that is kind of handy is buying 1 quart bottle also...it's easier to pour out from the quart bottle as you mix. I used a funnel to keep refilling my quart bottle from the gallons. So that's a recap of the paint materials. Additionally, make sure to have some GOOD QUALITY paint mixing sticks on hand. They had some cheap ones that flaked wood particles, or some sanded and rounded ones that did not. Also leave with maybe 30-50 filter funnels (free usually), and I highly recommend buying a 50 or 100 pack of the paint mixing cups on Amazon. Then get some small ones from the paint shop because you'll want a dozen or so of those too. For respirators, the full face one worked out very very well for us. I probably went through 10 pairs of filters and prefilters for those, or more. If you have fresh cartridges you won't smell a thing. If you smell anything, stop what you're doing and replace them right away. All these cartridges and mask items I got from Amazon, so it only takes a couple days to refresh your supplies. Plastic: I needed 2 rolls...I can't remember how long they were...at least 100' each. The larger of the 2 sizes. Inline air filters: You probably want to not only have a nice regulator/filter, but throw in the disposable inline filters as well. My Harbor Freight ones broke easily. The ones from the paint shop didn't. I went through about 4 or 6 of them. That should get you started! |

That about covers the actual paint and chemicals.

For my spray gun, I use 2 guns. One is a Sata Minijet...not even sure of the exact model, that I use for smaller parts. The other is a nice Satajet RP Digital 2 with a 1.4 tip...similar to the Satajet 2000 RP model. This gun is probably better suited for home use than the newer guns are. It requires approximately 12cfm at 35psi supply, but you spray at 24-27psi at the gun. It has a built-in digital display and regulator on the gun handle. The newer guns use fewer turns for the fluid knob. Mine is 5-turns to full open flow, and you almost always run it at fill wide-open fan. You spray at a distance of maybe 6-8". This gun lays down the paint pretty quickly, so you have to keep your arm moving all the time.

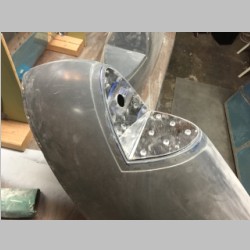

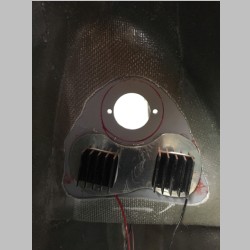

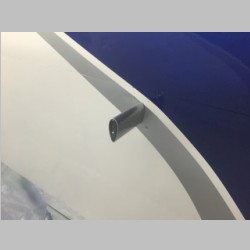

Below I have a couple of things to mention. The first 2 photos are just pics of my wingtip nav lights, after cutting the holes in the wingtip for them. I'm glad I went this route. I think my brightness may be overkill though. They are darn bright!

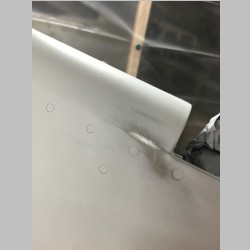

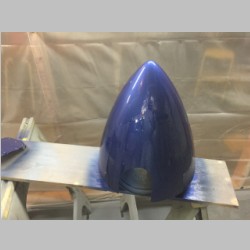

That 3rd pic is some spot putty I used for filling pinholes. It was INCREDIBLE stuff!! I was able to fill all of the pinholes in the spinner in about 15 minutes, and after another 15 minutes of sanding the spinner was ready for priming. Amazing stuff.

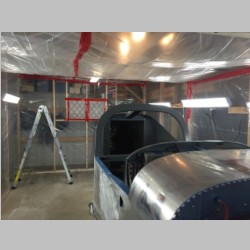

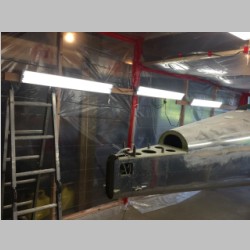

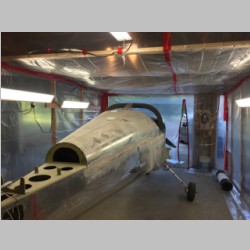

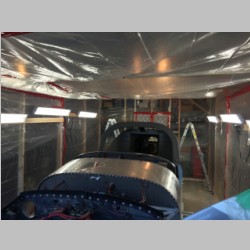

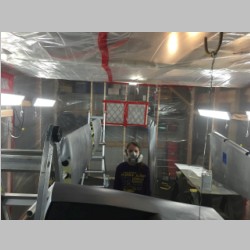

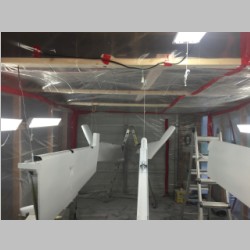

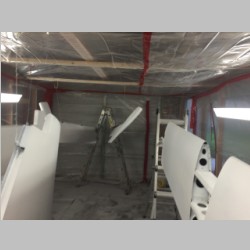

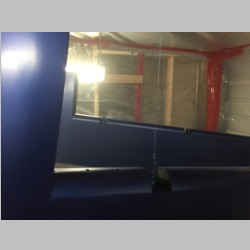

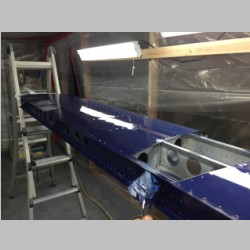

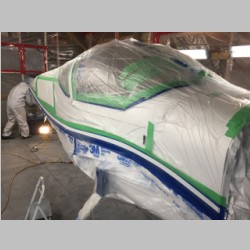

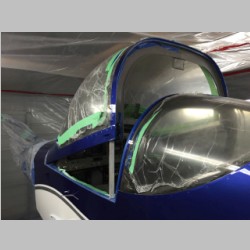

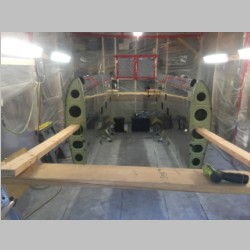

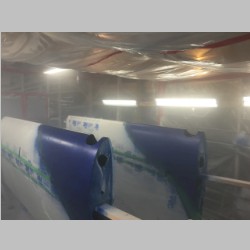

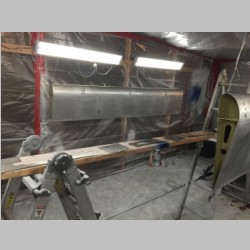

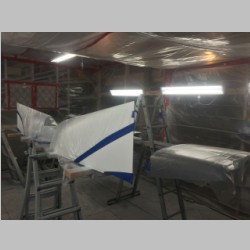

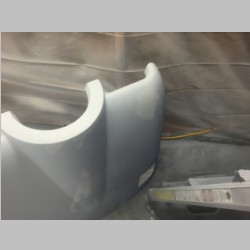

In this first set of photos we aren't actually going to start by painting the fuselage. For about $350 in materials, I was able to build a 12' x 22' paint booth in one of my garage stalls. It would have been even easier if I had a smaller garage with high ceilings, but I built an entire walled frame and put plastic on the inside of it. Then with 2 pusher fans on the inlet filters, it keeps the room positively pressurized. 2 exhaust filters trap all the paint overspray as it leaves. I wanted a positive pressure booth because otherwise when you open the door, dust gets sucked in, and this also allowed me to build the booth out of wood (easier than PVC, and easier to re-sell when you're done), without getting wood dust inside. It ended up being very air tight, and will work amazingly well! Roofing paper on the floor protects the garage floor.

To quote a popular phrase seen in the movies these days, "This S**t just got real!"

I learned a couple more things along the way to finishing this batch of parts. #1 is that while for many years the only real way to paint aluminum successfully was to use an etching primer, apparently now the adhesion is good enough with epoxy primers that those can be a suitable aluminum primer too. A pro shop that is currently doing a friends plane used Epoxy primer rather than etching primer. My guess is that while the adhesion may not be 100%, because it's non-etching, it's probably so close now that it's negligible in difference....but that they are probably doing it not because it's the best adhesion but for 2 other reasons. 1) Chrome etch is fairly nasty stuff. Eliminating this will eliminate one more chemical that has to be dealt with. And 2) by eliminating etching primer and using epoxy on everything, you can more quickly get to painting each piece. In my case, on fiberglass sections, I used Epoxy Primer, High-Build primer, Sealer, then either the single-stage or base-clear paint. And, on Aluminum I used Etching primer, Sealer, then the paints. The aluminum doesn't really need the high-build stuff. So, by going the other route, I could have spent more on epoxy, but eliminated the DX1791 and DX1792 from the mix, and saved a bit of time. When I paint my next plane, I think I'll go that route. It may even save a slight bit of cost.

Sideline jobs

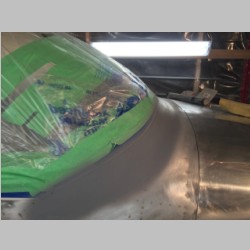

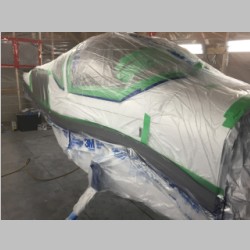

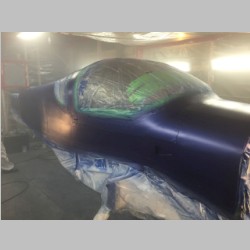

Fuselage Paint

Striping and Numbering

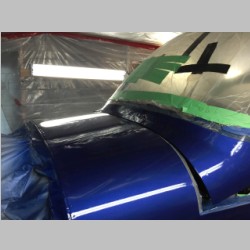

Finishing the Fuselage

Painting the Wings

Wingtip Design

Re-Paint wings and Paint Control Surfaces

Final Parts Painting

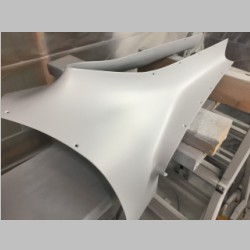

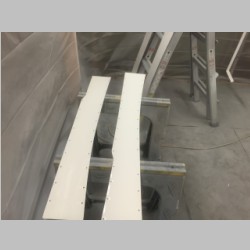

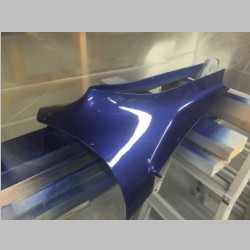

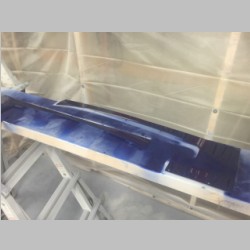

So above are the pictures of the remaining parts. This will end my section on painting the RV-14...the only painting left is a couple of touch-ups on chips, and the wheel and leg fairings once I start on them. Now it's time to head to the hangar and get this thing assembled and flying!

Previous | Site Home | Next