Mag Failure SB1-15A @ ~305 Hrs

Feb 2019

This is one of those write-ups that although a pain in my butt

to have to deal with, is actually a bit fun to document and

write about. Magnetos are definitely and older technology,

and there I times I kick myself for being a semi-luddite.

You see, I did, on both airplanes, make the jump to Electronic

Ignition, with both planes having the Lightspeed system.

It's been a fantastic system. But I never had the

confidence to go completely mag free, so both of my airplanes

currently have one magneto, on the Left side. It's when

these Mags give me problems that I start to wonder why I don't

just take that extra leap. The truth is, I think at this

point I would, if I just took the time and effort to add a

standby alternator. I have dual-battery systems in both

planes, and I've got enough time on the ignition systems to

trust at least my Lightspeed. There are other good

manufacturers of E.I. systems as well, but some either have less

fully functional flying airplanes that use them, or perhaps a

shorter track record, so I have a hard time making the

jump. To be even more truthful, I was sold on Lightspeed

on the first day an airplane came rolling up to me running on

them, and I heard how it sounded. But I'd be willing to

look at a second EI system these days, once I get that

alternator. Maybe this is my year to shop at OSH.

The story with my Mag issue this time around, goes something

like this:

On the last couple flights, there was an engine stumble while

climbing out at maybe 800'. That alone made me curious,

but then the engine ran fine, so you kind of file it in the

"better watch for that" file, that you keep until you figure out

if you really have a problem. Fortunately, my next run-up

made it perfectly clear where to look. Too bad it happened

on the one good day we had in this official "most snowy ever

February in history" that we had here in 2019. As I did my

run-up, my E.I. side worked perfectly, but when I switched to

the Left system, the engine didn't even want to run. It

would very occasionally "pop" but it wouldn't run at all.

So at that point you know you aren't just missing a cylinder,

you're missing the whole ignition system. I did try the

insanity of "burning off the plugs", but knew that was going to

be hopeless, because in all my years of flying I've never had

more than 1 plug completely foul, and it's never been as bad

running as this was. So time to taxi back to the hangar

and tear it apart to see what was up.

Of course, I started with the simple things. I pulled the

plugs, inspected them (all pretty good), tested their resistance

(all between 1250 and 1450 ohms as best I could tell), and

checked the wires, springs, and contacts inside the plug.

I didn't find anything bad. Time to move on to the more complex

stuff, so lets add some pictures.

|

|

|

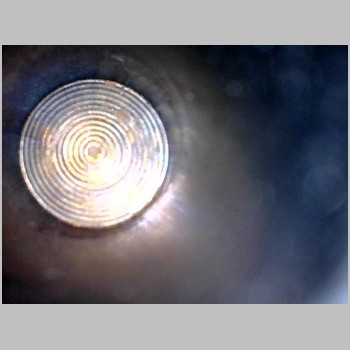

| After checking the wires

themselves, it was time to look at the Mag contacts.

Luckily I bought a really darn cheap approximately 1/4"

head wireless inspection camera that works with iphone,

sometime last year on everyone's favorite small-business

killer, the ever popular Prime Shipping 2-day

website. The 3 pics above were as good as I could

get by holding my iphone up to the mag. Luckily the

RV-14 has a fair amount of room. But with that mini

cam I could actually inspect right into each

contact. You can see in the first pic below that one

of the terminals had a little bit of carbon forming.

I have since cleaned that out with some q-tips and

alcohol. I also inspected the springs on the wires

at that end, and alcohol cleaned the rubber tips.

When finished I applied dielectric grease to the rubber

parts on both the spark plug and mag end, to hopefully

keep things more sealed up. |

||

|

|

|

|

|

|

|

|

|

With the mag end finding nothing glaring at me so far, it was time to grab the buzz box and check the timing. I got mine very very reasonably, years ago for my RV-10, from this place: http://www.magnetotimer.com/ They're only $25 and work fine. I was surprised to see that the timing was off. The IO-390's timing spec was 20 BTDC, and this was running maybe 6 degrees off. That was pretty unusual to me. I knew that if I were going to have to re-time the engine, I wasn't going to do it without first finding out what was wrong inside the mag. I'm not used to my timing shifting that much over time. So a short time later I had the mag on the bench. Now, I'm absolutely no mag expert, but I compile data well. A real mag expert is someone like Mike Busch, and here's a link to a great article on Mags that he wrote. Sometimes, however, I can interpret things in a more clear way than I read them when reading other data. That led me to dig up my old web page on MyRV10.com where I had a whole compilation of magneto timing material. Here's the link to Tim's Updated Slick Timing Document. This page has actually ended up giving me a few chuckles. First, like I said, I'm no magneto expert, so I refer back to it myself whenever I have to work on mags. But one time my Ex-wife's now 2nd ex-husband told me that he was at an A&P class, and other A&P guys were talking behind him about a good reference to help understand mags...and mentioned it was on MyRV10.com. He overheard that and told me. I was shocked. People actually read this drivel that I write? I thought I was doing it for myself, so that as Alzheimers kicks in, I can remember it all. Flash forward a few years and I got an email from a factory plane rep who was helping a person in Africa of all places, work on a plane of theirs. He actually used that same link to help the guy better understand the mags. Like I said, I'm just a data gatherer, but hey, if it helps you all out, I'm glad it could be of service. Anyhow, with the timing that far off, I opened the mag. I always move slowly with mags, because they intimidate me still, due to the long gaps of time between working on them. I do like spare parts, and keep spare contacts, and cam with me wherever I go. Also, I have always carried with me a T-118 Timing pin, and the T-150 E-Gap gauge, and after this experience I bought a 2nd set so I could carry one in each plane. Additionally I've ordered a couple spare condensors, as I realized I don't have a spare for them. I take pictures of these things because I want to fully remember the exact orientation of every wire, gear, pin, and label as I tear things apart. I'm not sure if I'm smart enough to simply throw all the parts on the bench and then figure it all back out from scratch. |

||

|

|

|

|

|

|

|

|

|

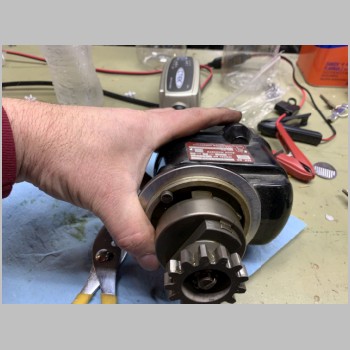

As I got further into the mag, I kept snapping pics. You can see the small drive gear, with it's "L" marking pointing to the notch in the distributor cap, and the pin in the "L" hole of the mag. This is because it's a left hand rotation mag, and I pulled it out with the cylinders at TDC, pinning the mag gear in place so it won't rotate. Just make sure you don't rotate the prop with the pin in, and that the timing marks are still at TDC before you insert the mag when you're done. Still, I was finding nothing that looked bad. The points were wearing evenly and were in good shape. I used a capacitor tester and although maybe not a perfect test, was able to test the capacitor (condenser), and it tested within spec and charged and discharged appropriately. The Cam appeared to be in OK shape, as did all the teeth on the gears, and the carbon brush was fine. So far I wasn't finding anything. |

||

|

|

|

|

|

|

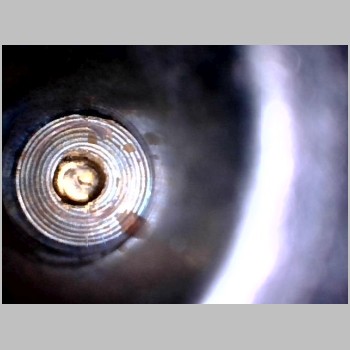

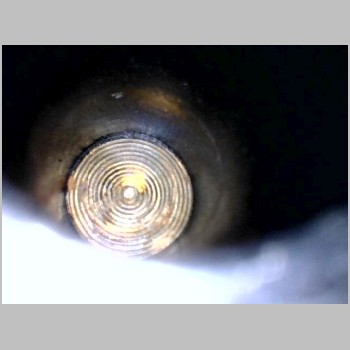

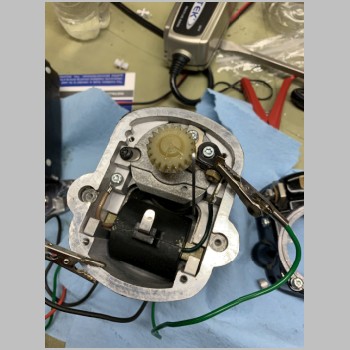

I decided I was going to have to dig even deeper. Time to pull off the distributor cap, and also check the e-gap for internal timing. It was then that I struck troubleshooting gold! As I removed the main gear from under the distributor cap, i looked at the "wiper" for lack of better terminology...the electrode that sends the spark from the coil thru the carbon brush, up the gear shaft, out the wiper to the 4 individual terminals for the spark plug wires. That wiper was loose, and not just a little loose. Knowing that the job of this thing relies on the ability to transfer electricity from the shaft down that arm, you would NEVER want that arm to be loose. If it isn't a pretty tight fit on that shaft, there will be a gap. Where there's a gap, there is spark. Where there is spark, there is erosion. As you can see in the video below, I could easily pick out that arm and there was a TON of gap around the shaft, and plenty of erosion had happened. |

||

| I did remove the copper arm, polish it up to inspect it, and the put it back in place. But something was clearly wrong, because that arm either had to be pressed in to the shaft, and wasn't, or molded into the plastic and wasn't any longer. My heart sunk because I knew I was going to have to order parts, or, rob them out of the brand new 4370 that came with the engine that I have stored in a sealed box. Time to pull out my Champion Slick Service Manual L-1363F (G is now current at the time of this writing but F was all I had on hand), and figure out what parts I needed. As I got into the manual I located K3822 as the Distributor block and Gear assembly. As I got online to buy a K3822, figuring I'd have to spend more than I would imagine, I had NO IDEA it was going to be as outrageous as what I found. The only places that sold the K3822 sold them for $399 and up for the most part. That's absolutely insane for a few plastic pieces and a couple metal ones. Had this been for a car, it would be $30. For a boat maybe $50. But $400??!!! The more I dug in the more I found that really, what you would end up buying is either a 500 hour mag kit, or a rebuild kit. The latter costs more like $680 and contains those parts and a few more. I remember back in 2001 or 2002 buying a magneto for $500 complete, but now they're almost $1300!! I started to get pretty down on the whole mag idea once again. This seems to happen every few years as you have mag issues. Ultimately if I can buy an E.I. system that uses aviation plugs on the bottom, I'll probably end up doing that some day. But, being aerobatic, I want plug wires that bolt on securely, and I would like a timing curve that is more conservative as the Lightspeed, simply because I trust that box and want that to be the most advanced sparking system I have. Here are a couple of links for rebuild kits, for reference: https://www.aircraftspruce.com/catalog/eppages/slickmagmaintkit.php https://www.aircraftspruce.com/catalog/eppages/replaceslickmag.php But keep reading, because it gets better. |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

After continuing for maybe an hour, to search for a cheaper way to buy either just the gear, or the distributor block and gear assembly, one google search turned up a service bulletin from Diamond Aircraft, referencing a Champion service bulletin SB1-15. That showed me EXACTLY what I had just experienced...the failure of the electrode on the gear. It covered a range of serial numbers very close to mine, but not necessarily including mine. Time to google that further. Sure enough, it had been updated to SB1-15A, and that one DID include my serial numbers. Here's a link to SB1-15A for you to check out.

The short of it is, indeed, you can buy just the gear, despite that part not being listed singly in the manual. The part is K3008 for the gear only, and is available from multiple places, including Aircraft Spruce. Also, Champion will take your mag back and fix it for you and ship it back to you, without charge for the parts or their work. They won't pay for your A&P's labor, however, but that didn't concern me in my situation. The limitation is, however, they will ONLY fix the gear for you. If you have other issues, they won't fix those issues. So, for people who are willing to tackle the job themselves, it may be best to just do it yourself. When I called them, they also pointed me to another SB to pay attention to that is more general, about timing shifting in mags...74-20-001. Here's a link to that SB as well. I decided that for the long term, maybe I'd just order some points and gear and replace them both.

|

Various Mag Parts

for Reference

(This is as much for me for as it is for you, and applies

to my RV14's 4372 (and un-used 4370) Magneto, as well as

some parts applying to my RV10's 6351 Magneto)Note: Pricing below may not be current when you read this |

|||||

| Item |

Spruce p/n |

Spruce Price |

Optional Part #'s |

Optional Part Price |

|

| T-150 E-Gap Timing Gauge |

12-00302 |

$16.60 |

|||

| T-118 Timing Pin |

12-01441 |

$7.95 |

|||

| K3008 Gear Kit |

08-01370 |

$99.75 |

Kelly ES510406 (08-16232) |

$74.85 |

|

| K3984 Condenser/Capacitor Kit |

M3183 |

$159.75 |

Kelly AK-3984 (07-02451) |

$132.75 |

|

| K3215 Slick Carbon Brush Kit |

M3215 |

$14.50 |

AM-3215 (07-02454) |

$10.50 |

|

| M3081 Contact Point Kit with Cam |

M3081 |

$68.75 |

A-13081 Someone get me the Kelly # if you know it please |

$57.75 |

|

| M2556 Slick Cotter Pin |

M2556 |

$1.25 |

|||

| M3426 Mag Gasket (Slick) |

M3426 |

$16.50 |

Alternates listed below slick part |

||

| SA534750 Mag Gasket (Superior) |

08-11164 |

$.75 |

(now that's cheaper, eh?) |

||

| LW12681 Mag Gasket (Lycoming) |

08-00285 |

$1.70 |

|||

| SL12681 Mag gasket (Superior) |

08-11573 |

$.93 |

|||

| M1827 Slick Rotor Cam Grease |

08-04633 |

$2.25 |

|||

https://www.aircraftspruce.com/catalog/eppages/replaceslickmag.php

https://www.aircraftspruce.com/catalog/eppages/kellyamagaccess.php

https://www.aircraftspruce.com/catalog/eppages/4300svcparts.php

https://www.aircraftspruce.com/catalog/eppages/6300svcparts.php

https://www.aircraftspruce.com/catalog/eppages/superiorlyc0320b.php

So after buying some replacement parts and some spares, the end process is this: Buy the replacement slick K3008 gear from any of their distributors, replace it, and then work with that dealer (in my case ACS) to warranty it and get a credit for your old part. They will work with Champion/Slick to return it.

So what happened exactly? Well, I'll tell you what's opinion and what's official. Officially I spoke with someone at Champion who was very nice and told me that the original failure was caused by a manufacturing defect in how that wiper was molded into the gear. Apparently there was a period that either contamination was present or pressure/heat wasn't correct, and how they place that part is push the wiper down over the shaft, then a heated piece comes down and melts the plastic over the metal wiper to lock it in place. Some of these weren't locked tight enough. That leads to vibration, and vibration to wear, wear to increased gap, and increased gap to erosion at a faster rate due to spark. So then mine got so hot and loose that it just plain came free. And that was in only 305 hours.

The fix? Well, first, they now ensure that the plastic hold-down is molded better. But also, that part now changed from copper to Monel for a metal. Much stronger and wear resistant. The 6-cylinder mags have always been Monel, but somewhere years ago they switched to copper in the 4-cylinder mags. Probably some idiot bean counter trying to save .03 cents. But they are now making them all in Monel, which will lead to them being more durable. So once you have done this S.B. you should not have that happen in that way again.

The only catch I've found so far is that parts are still semi-scarce. For a while Champion had production issues, but now they say they have many, but most dealers are waiting for the parts. For me, I swiped mine from my other brand new mag, so I could put a few hours on it before I warranty the part out. I may as well, because even if I sell that mag, I'm not going to sell it with that known suspect part with a copper wiper.

Hopefully this page proves useful to some other 4-cyl Lycoming owners who are affected by this same SB. And, if you have any good cross reference info for me to complete some more of that pricing chart above, send it and I'll update it. While on this part I'd replace it with a slick for warranty reasons, I'm not sure I'm very happy about the price gouging, so I'll use Kelly or other wherever possible. Normally I'd buy only original brand parts, but I feel many of those parts are being sold at unethically high pricing, so it's kind of my "protest via wallet" that I will do. And in the long run, I think I'll spend the cash on a backup alternator and a 2nd E.I. system so I never have to deal with mags again.

MyRV14.com Home | MyRV10.com Home