|

|

|

|

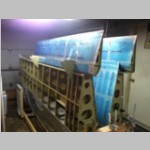

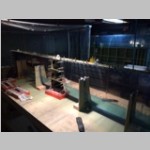

So after testing the tanks and

finding no leaks, I got them mounted to the wings along

with the leading edges, and now they sit nicely and safely

in the cradle. I still haven't done the bottom skins

because I haven't done any of the wiring or installed my

pitot tube mount yet. Once I do that, I can finish

the bottom skins. I also kind of wanted to wait until near

the end, so that I've bought my autopilot and installed

the servo. Again, I want to use the same TruTrak

VSGV which is now renamed, in my RV-14 as I have in the

RV-10, and they tell me the bracketing will fit fine for

my install. But I'll wait until just before paint to

finish everything, except I'd like to get the pitot tube

mounted before that.

|

|

|

|

|

|

|

|

|

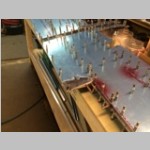

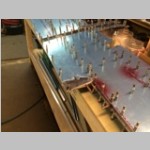

| The flaps went together real

quickly with no issues, other than I think I have a slight

twist in my Left flap. When you install them onto

the wings, you can look at the rivet line as it lines up

against the wing skins, and tell if you have a twist or

not. I am not sure if I'll end up re-building a flap

later or not, but I'm going to paint it and fly it this

way for a while and see how it goes. Make sure when

you rivet the bottom skins on that you have the right

angles to the flap brackets and that the flap is held down

on a flat surface and everything is lined up well. You can

see how I had them held down on the bench with lead shot

pouches and a 2x4, but I didn't do one final check of the

brackets to make sure I had everything perfect before I

did the trailing edge. Honestly though, I think the

twist comes at the time you put the bottom skin on, so

before doing that, get everything in the proper

alignment. When riveting the trailing edge, you can

mess it up and have it come out bent (mine didn't), but

that isn't the same as the twist I'm talking about. |

|

|

|

|

|

|

|

|

I didn't take too many pictures

while assembling the ailerons, but they went real

smoothly. There was a bit of confusion to the plans

when drilling some of the holes into the steel

counterbalance tube. I think it was poorly copied

and edited from the RV-10 and they have you do things

twice if you follow the plans. Think through that

area a bit first, because it works out better if you skip

the first pass and just do the 2nd. Maybe

they've even revised it by now, but either way, the

ailerons are pretty easy to build.

|

|

|

|

|

With the ailerons built and

stuck on the wings, it is now time to line everything up

to install the wingtips. With the twist in the flap

that I have, this means I'll want to do a little bit of

adjusting to the aileron and flap alignment before I start

mounting the tips. See, the flaps are your base for

aligning everything. You can then line up the

ailerons to the flaps. Then you line up the tips to

the ailerons. If you have everything straight and

perfect, you can avoid a heavy wing. With a twist in

my flap, I don't want to build the alieron and tip to

match it perfectly, or I'll just make the problem

worse. By making sure the nose to spar gap of the

flap is straight and consistent all the way along the

flap, I can use that as the basis for "zero" (I'm guessing

that's the same -3 degrees as the RV-10) point for

aligning everything. You want the tips and ailerons

aligned to that -3 degree reflex flap setting so that you

have minimal drag in cruise configuration.

|

|

|

|

|

|

|

|

|

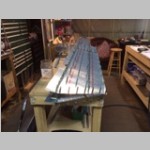

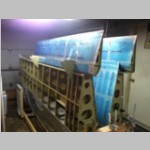

With all of those wing steps

done, my wing parts pile was getting pretty small.

Since I'm waiting a little longer on the wingtips, it was

time to dive in to the empennage kit and start getting

those parts put together. The faster I move through

these little things, the cleaner the garage can

stay. I can't wait to get the tailcone done.

Once that's done, it's fuselage time and this thing will

start looking like an airplane.

The Vertical stabilzer is very much like the RV-10 in its

construction. It's a little shorter, so there is a

missing center nose rib which on the RV-10 was a "gotcha"

where if you didn't taper the rib well, you'd have an

outward dent in the skins. On the RV-14 plans you

can see that Van's realized this and there are numerous

references to making sure the nose ribs are going to go

together properly. The vertical stabilzer builds

faster than most any part on the plane...zero to

satisfaction in no time.

|

|

|

|

|

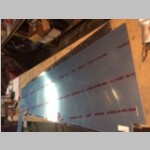

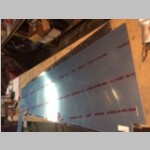

Although it's been a pretty

busy winter for everyone in the family, the kids got out

and helped a few times over the past couple months.

Things sure go faster when they're around, especially on

deburring days. They hate that step just as much as

me, but it goes so much faster with 3 or 4 people doing

it. Below in the 4th photo and some 2 rows down, you

can see the RV-10 rudder skin laid on top of the RV-14

rudder skin. I'll be rebuilding my rudder sometime

this year, and hope to paint it at the same time I paint

the RV-14. I plan to use the same exact paint and

color choices to simplify any repairs down the road to

either plane. It'll give me a good opportunity to

repair 8 years of chips on my wheel fairings too.

|

|

|

|

|

|

|

|

|

The keen eye will notice that

I've added an access panel in my RV-14 rudder. This

is because I decided that I will likely add the same

electric rudder trim as I have in the RV-10. It

works exceptionally well and is easy to do, so I added

that panel right now so it can be painted up with less

rework to do later. I don't know if I'll actually

add the servo before I fly, but at least the largest part

of the job is done.

Below are a couple of photos of the rudder sitting next to

the vertical stab.

|

|

|

|

|

|

|

|

|

|

|

|

|

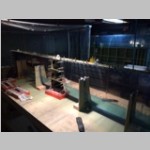

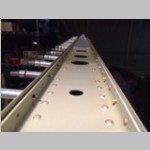

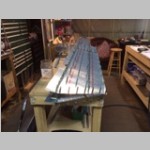

The horizontal Stab is a big

piece to work on, but it's not ultra complicated. It

definitely is one that leaves you a feeling of

accomplishment however, due to it's size. After

completing this, the pile of parts left in queue is

getting much smaller, with only the elevators and tailcone

and a few other things. I did have a couple of

slowdowns due to the priming that was required before

certain parts could be assembled, so rather than follow in

complete order of plans, I tried to get everything to the

priming stage at the same time, and get it all primed

before assembly.

|

|

|

|

|

|

|

|

|

You have to be careful when it

comes time to throw the whole rib/spar assembly into the

skins. There are some steps where you leave some of

the skin and rib holes un-dimpled. This is because later

the fiberglass intersection fairing will fit over those

areas and you'll be installing nutplates. Even after being

aware of it and trying to remember to be careful and line

up the proper bottom side of the spars, with the proper

side of the dimpled ribs and stiffners, and then the

skins, I still found for a minute that I had the stiffener

assembly in upside down, so had to pull it out and flip it

and re-insert. Just talking about it makes it sound

like a big deal, but in reality it was a 3 minute

job. Just be aware that when you get to that step,

you really have to know which side of each spar is top,

and insert the rib assembly in top-side-up, and then get

the skins on in that orientation too. The assembly

itself goes very easily and I did the entire horizontal

stabilizer alone, with no real assistance from the

family. It's not an overwhelming step, despite the

size.

|

|

|

|

|

|

|

|

|

Here are just some various

assembly pictures, not that they're pointing out anything

in particular. It's just nice to see it all coming

together.

|

|

|

|

|

|

|

|

|

Believe it or not, the

Elevators to me are a bigger pain in the butt than the

horizontal stab. There is a lot to deburr, and there

are lots of small pieces, so there is quite a bit of time

to getting them to the stage to rivet anything. As I

write this, I haven't finished anything past this part of

the elevators because it's been either too busy or too

cold. Today, 3/2/14, it's down in the -6 to -15F

range again, so it isn't going to be a building day,

although the sun is out and it's beautiful looking

outside. That's why I'm spending time getting these

photos out. If I remember right, I had one whole

work day into just cutting, deburring, and preparing the

parts, and then had another day into assembling the

elevators to the stage of these photos.

|

|

|

|

|

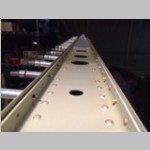

One thing that is very

different in the RV-14 from the RV-10 elevators is the

trim design. The RV-10 used 2 trim tabs and a

special mechanism to actuate them remotely with push-pull

cables and a cam to get the deflection right. It was

both complex and simple at the same time, but also meant

you had to build two trim tabs. The RV-14 changes

things drastically in that you only have one trim tab, and

the trim servo is located within the elevator

itself. So, there will be no cables other than a

wiring harness that run into the elevator. I think

it's a great little design. They did a bunch of

custom special parts to mate up inside the elevator to do

this. My next tasks are to prime and then start

riveting things together, and I think it'll all go

together pretty nicely. The new elevator trailing

edge is a completely new design too, but I find it's easy

to build and should work out fine.

|

|

|

|

|

|